Future of 4D printing

Dr Connor Myant

Lecturer, Dyson school of design engineering

3D printing is used in a number of industries, from manufacturing to the promises of the pharmaceutical and healthcare industry. Now that 3D printing is three decades old, Dr Connor Myant is looking at the next logical step: 4D printing, which involves the creation of objects that change shape over time and in response to stimulus.

Until now, 4D printing has been used to create unravelling flowers and artefacts, but we are now nearing the point where we can employ 4D printing in commercial applications, by creating deployable structures that self-assemble on demand. This presents a huge opportunity in terms of developing complex products that perform a multitude of functions.

What if we could enable seamless systems?

What if we could create structures that self-assemble on demand, significantly reducing construction times? What if we could create objects that change their shape intelligently, in a pre-programmed manner or in response to their environment? At present, an aeroplane consists of 6 million parts and takes around 80 days to build. Imagine instead an aeroplane wing with no hydraulic rams, with no oil pipes, with no machine elements; just a single, responsive surface that can be tuned to the optimal aerodynamic shape. The ability to create such objects will dramatically affect build times, assembly times and maintenance protocols, improve performance and ultimately reduce cost.

4D printing in the near future…

4D-printed deployable structures could be used in consumer goods, for example flat pack furniture or clothes and trainers that react to their environment to improve comfort. Moving forward, we could also imagine building facades that react to the weather to regulate building temperatures, or deployable buildings to be used in high-risk zones. Reaching further afield, because construction in space is difficult, dangerous and expensive, the ability to launch self- assembling structures into space could dramatically improve space exploration.

4D printing in the far future…

There stand to be many benefits of 4D printing in the healthcare sector; for example, imagine implants that don’t require evasive, time consuming, hazardous surgical procedures. Dr Myant is currently working on windpipe surgery to imagine how we can move from using current bulky products to a simple foldable structure.

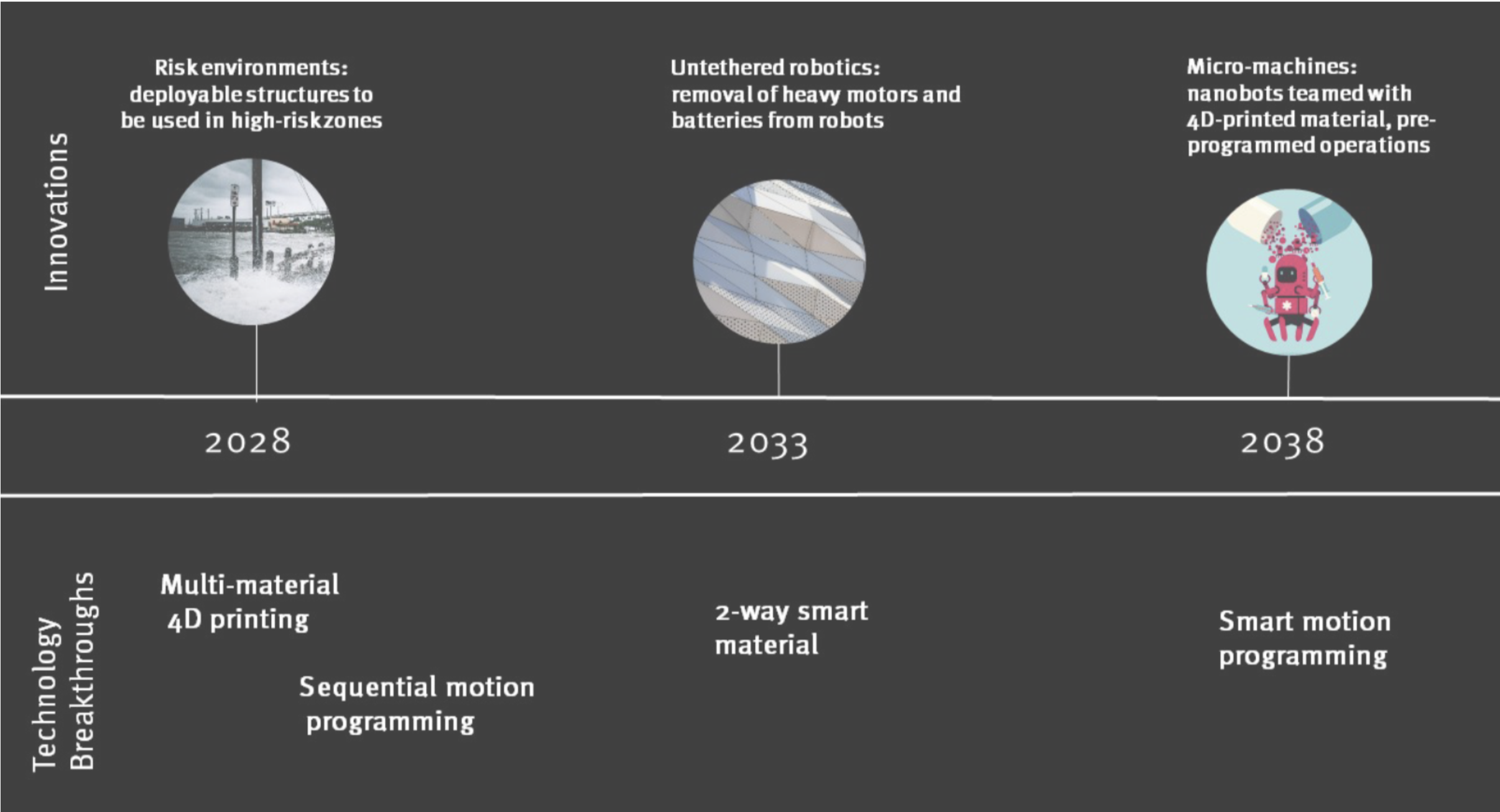

What might other future applications of 4D printing be? Here are some technological speculations: